For a little over a decade, the rare sight of a passive aerodynamic modifier could be seen on highways across America.

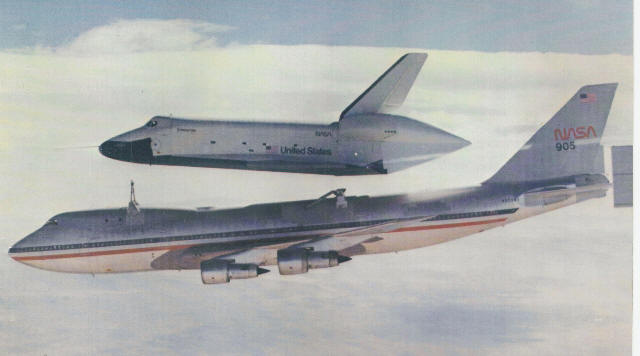

Depending on your vantage point, it could look like the tail of the Enterprise Space Shuttle… or perhaps a deflated pastry box.

TrailerTail® was a hand-operated origami structure that reduced aerodynamic losses at highway speeds by smoothing the sharp discontinuity between a tractor trailer’s square posterior and the wake of air behind it.

The operator had to manually deploy it before getting on the highway and stow it when not required.

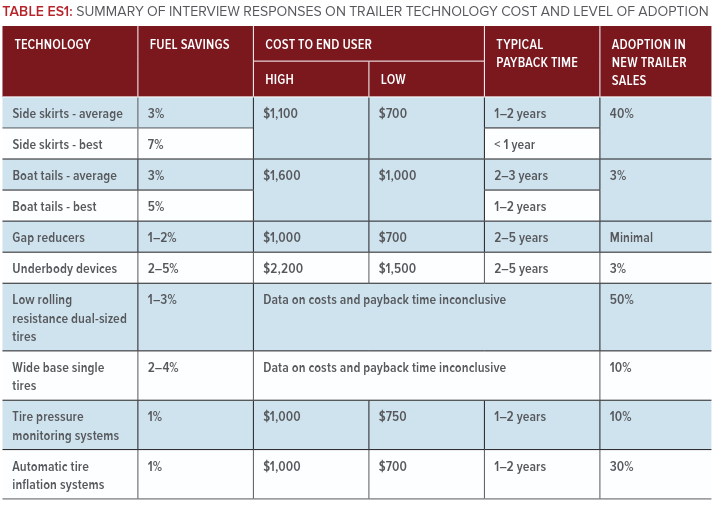

Marketing materials and research studies put the fuel savings of boat tails like TrailerTail at around 5%, with upfront costs of less than $1600.

A 2,000-mile trip that would have taken 200 gallons of diesel, costing $720 at $3.60/gallon, might with TrailerTail only burn 190 gallons. The trucking operator could pocket the unspent $36 of fuel.

Over the 60,000 to 100,000 miles driven that is typical of haulage trucks, TrailerTail could make up almost $18,000 in savings per truck per year, in the days when diesel was flirting with $4/gallon.

Fortunately, for the trucking industry, fuel prices relaxed a few years after the TrailerTail’s introduction. The US national average diesel price dropped ~20% from ~$3.60 to $2.80 per gallon between November 2014 and February 2015.

This wasn’t as lucky for the owner of the TrailerTail brand, STEMCO, which had purchased its original manufacturer ATDynamics in early 2015, possibly near the peak of its valuation.

The acquisition provides ATDynamics’ EcoSkirt and TrailerTail products access to Stemco’s existing sales and support network. “We couldn’t be happier about this match,” said Andrew Smith, ATDynamics CEO. “In a few weeks, we’ll have an additional 40 salespeople around the country talking about the benefits of these products and delivering the $2 to $3 billion/year savings to the industry by adding the TrailerTail.”

CCJD

If $2-3 billion/year is the most the entire industry could save by reducing fuel consumption by 5%, they might find it hard to justify expending capital and operational costs on TrailerTail when the free market handed them a cool $8-12 billion cut in diesel costs for doing nothing at all.

By late 2020, STEMCO discontinued the product line, citing reduced customer cost savings and operator fatigue as primary drivers. It’s no longer even visible in their product catalog. Any currently deployed TrailerTails will likely be removed & recycled over the next decade once their articulations fail.

Will there be another commercial aerodynamic fairing retrofit kit?

TrailerTail wasn’t the first to bring streamlining to the roads. Engineers have been playing with them for the past century.

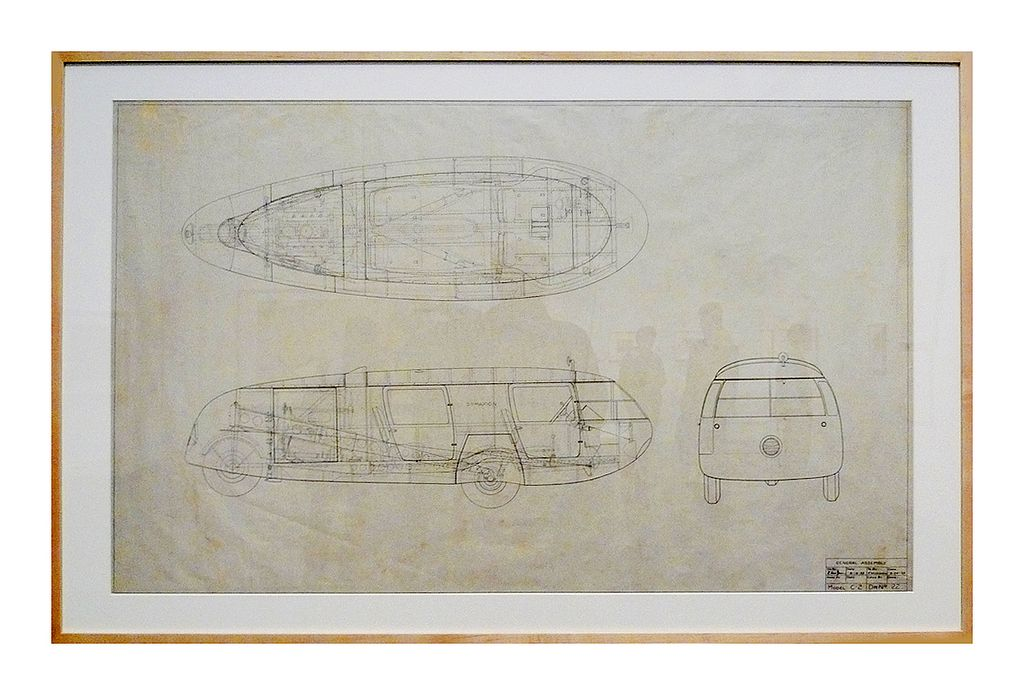

Buckminster Fuller had an interest in aerodynamic fairings in 1933. He envisioned a kind of flying car suitable for any American to use while commuting or adventuring. It was never more than a prototype, but it was widely viewed.

Cars in the mid-1930s and 1950s were built with enormously long and wide bodies; their styling was driven with the intent of appearing aerodynamic, but the bar was low. Chrysler’s Airflow was one of the first designs to have met a wind tunnel before the design was finalized.

Tinkerers didn’t wait for the mass market to advance the state of the art. In the 1970s and 1980s, and through the present, various enthusiasts have busily modified their cars to be more aerodynamic:

In most of these cases, performance isn’t precisely reported or estimated. Significant figures and error bars are an extreme rarity. Many rely on simple metrics: “did my MPG meter go up?” and “when I taped yarn tufts to it, did they wiggle the right way?”

Some bring a measure of rigor to the field. Julian Edgar is one such contributor, authoring multiple books on car aerodynamics and publishing several YouTube videos each month.

Other modders produce and document their creations for the adventure and engineering challenge of it all, some working within a mere a $5 budget.

Aerodynamic mods are sometimes paired with other augmentations. In the early 1990s, Alan Cocconi of AC Propulsion developed a series of aerodynamically faired pusher trailers, intended as range extenders for early EVs. A small internal combustion engine on the trailer enabled any EV to run like a series hybrid.

The pusher trailer has been revisited independently, many times, but has never achieved a level of success comparable to TrailerTail. The upfront cost (and risks involved in towing an external fuel tank) haven’t yet justified the relatively small range gains. Long-range, fast-charging EVs and inexpensive hybrids can yield 300-500 miles of range without resorting to unwieldy modifications.

The market has spoken. Trucking values observability, safety, and simplicity: 5% fuel savings wasn’t enough to justify TrailerTail.

The consumer car market also doesn’t have much interest in aerodynamic retrofits, either. Current-generation vehicle bodies achieve drag coefficients of 0.25 or better; there simply isn’t much more re-shaping to do, short of removing cross-sectional area.

Larger gains can be achieved by changing tires or improving driving habits.

In this author’s view, there might be a market for a compact, automatically-operated, trailer-hitch-mounted inflatable boattail for boxy SUVs, targeted exclusively at improving mileage on Cannonball-style road trips, but it’s quite small.

What’s your take?